Oluklu Panel Rulo Şekillendirme Makinesi

1.MEI SHUN CEO Mr. Wang is a very experienced Engineer in the cold roll forming equipment field, he's the Member of Working Group of Cold Rolling Forming Equipment (SACTC220WG4). That's mean Our company Mei shun could give you better technician services, we are good at the roll forming tech. research and development.

2.MEI SHUN machinery company, more than 20 high tech talents and more than 20000 square meter production workshop. We have more than 5 machine tool software patent rights, which is make our machine have more competitive advantage.

3. Factory use the world classic brand, like TAIDA (PLC). WEILUN (Touch screen). OMRON (Frequency converter and the encoder). Schneider (Electrical components). We work together make our machines stable and high effective running for long term.

4.We have our own professional processing of the design, develop and manufacture, also have proven machining technique. Each machine with strict quality control.

- Meishun

- Xiamen

- 30-50 gün

- bilgi

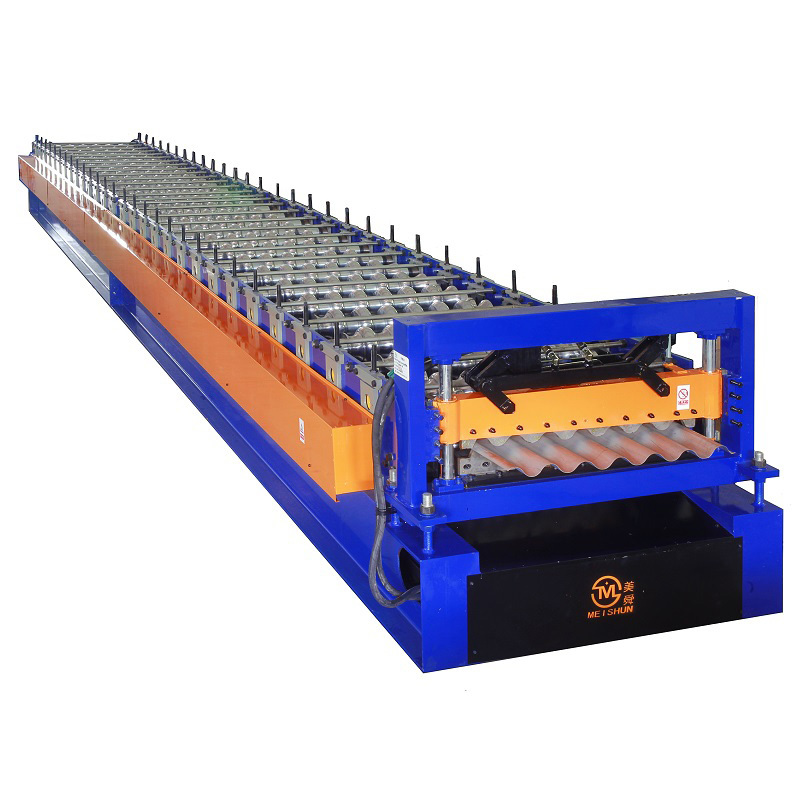

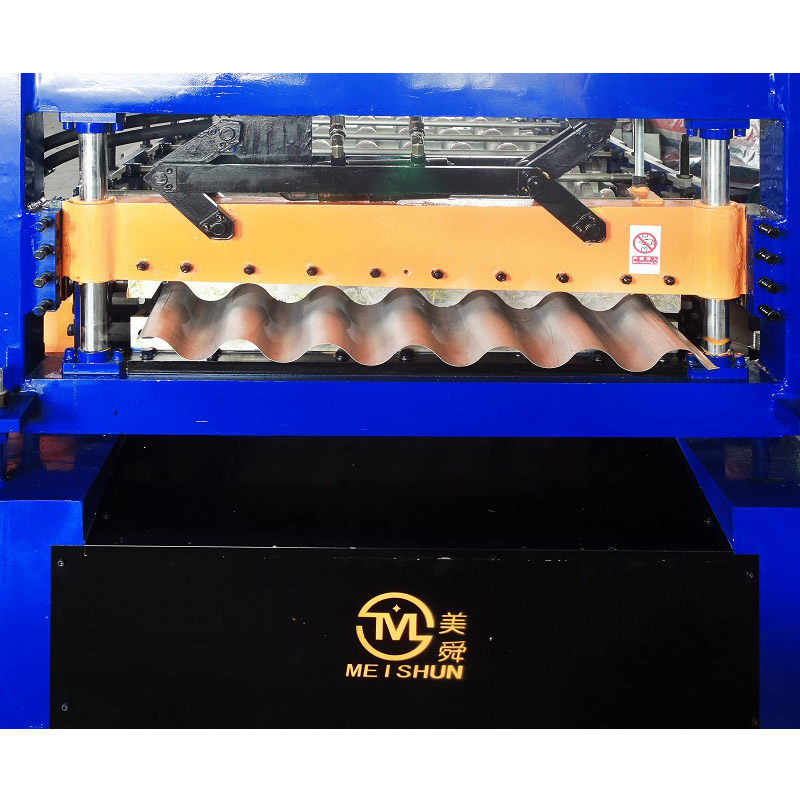

Corrugated Panel Roll Forming Machine

Corrugated Panel Roll Forming Machine is widely used for making various metal wall panels and roof panels for steel constructions, steel structure projects and containment systems etc.

Corrugated Panel Roll Forming Machine line consists of feeding unit, uncoiler, feeding guide, roll forming machine, cutter, automatic stacker, hydraulic system and electric control system.

| Equipment Parameters | |

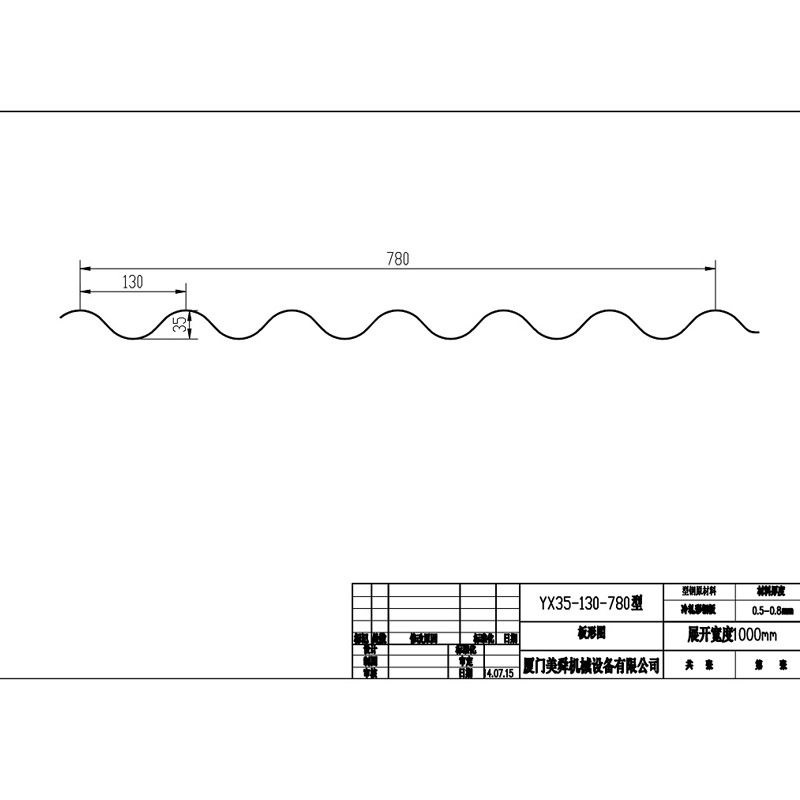

| Equipment Name: | MS35-130-780 Corrugated Panel roll forming machine |

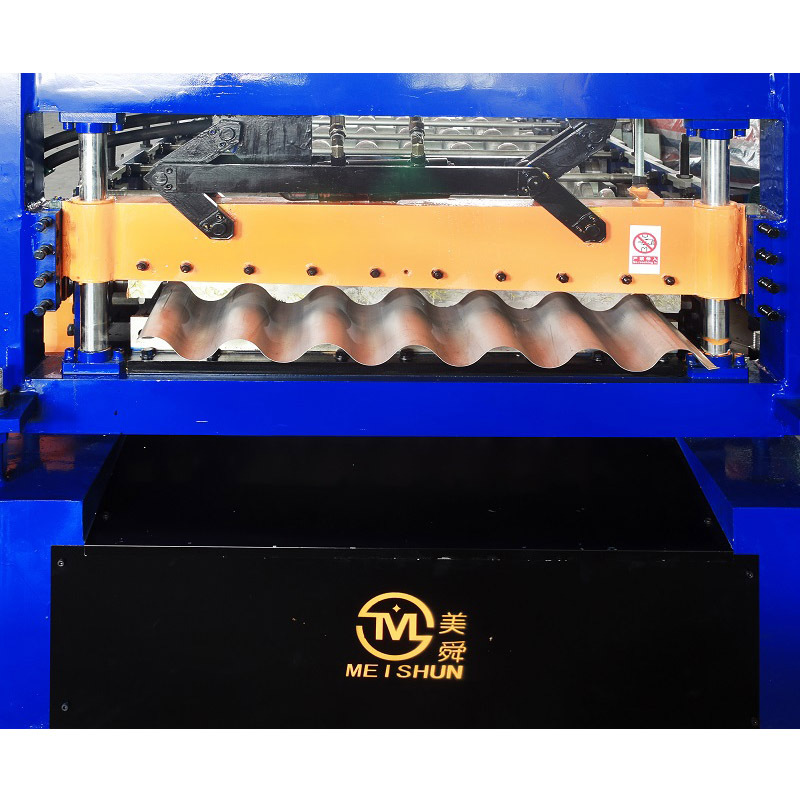

| Forming Passes: | 28 groups roller |

| Equipment Components: | Decoiler - Main Roll Forming Mill - Forming Cutting Device - Hydraulic Station - FLC Control Cabinet - Finished Products Rack |

| Equipment Size (L x W x H) | 12m x 1.4m x 1.2m |

| Main Motor Power | 7.5KW |

| Hydraulic Motor Power | 3KW |

| Equipment Total Weight | Approx. 10 tons |

The Corrugated Panel roll forming machine produced by our factory has the advantages of fast speed, high efficiency and stable operation, which meets the requirement of our customers in the building. Welcome sending your profile drawing & parameters, we will do customized cost effective and high performing roll forming machine as you want.